Grease application with eco-PEN dispenser Spray application using the eco-SPRAY Dispenser Automated grease application – precise and reliable TQ Systems, in Durach, manufactures collaborative robots that assemble themselves – among other things, with the help of preeflow dispensing technology. The precise eco-PEN and eco-SPRAY dispenser systems take care of the lubrication of gears, for example. The basic idea of letting … Read More

Highly Abrasive Materials Reliably Applied in Very Small Quantities

eco-PENs that are already in operation can be upgraded in a very short time, thanks to the spare parts kits. Test result after 120 hours dispensing: The standard rotor on the right, with a hard chrome layer, shows signs of wear over time when used with highly abrasive materials, depending on the process. Detail view rotor wear: Standard rotor left … Read More

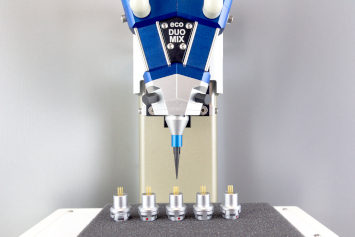

Potting of miniature connectors

High-precision dispensing for complete process reliability Miniature connectors must be absolutely reliable and have secure contacts. Two-component potting compounds such as PU, epoxy or silicone are particularly suitable for potting miniature connectors. They are especially impressive compounds due to their wide range of applications. Increasing miniaturisation of performance electronics and improved sensor technologies increase the demands on dispensing equipment, i.e., … Read More

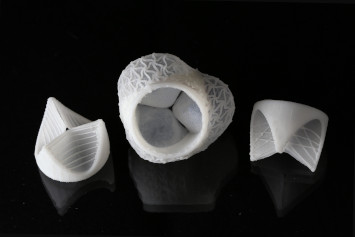

Bioinspired Artificial Heart Valves Made by Silicone Additive Manufacturing

preeflow® eco-PEN300 “prints” synthetic implant In an additive manufacturing process, virtual heart valve models are created with the aid of a CT scan and a preeflow eco-PEN300 one-component dispenser: Fergal Coulter from the “Complex Materials Group” of ETH Zurich undertook research for medical technology – more precisely for the additive manufacturing of artificial heart valves. They were manufactured using custom … Read More

Medical Wearable Dispensing Application

Dispensing of a high viscous grease with an eco-PEN330 preeflow dispenser Most people think of smart watches when it comes to wearables. But there is much more! On the market of consumer electronics, you can find for example hearables, augmented & virtual reality glasses or smart rings. In the sports sector there are fitness trackers, sports watches, smart shoes, and … Read More

Loudspeaker Bonding in Perfection!

Precise adhesive dispensing to components Thanks to its experience and reliability preeflow is the perfect partner in numerous dispensing applications – also when it comes to bonding loudspeaker components. In the loudspeaker bonding a great value on exact processing is placed to achieve an outstanding sound experience and create long-lasting products. The loudspeaker manufacturer’s latest technical innovations place high demands … Read More

A Variety of Dispensers for Micro Dispensing Applications

Covering the entire production process with one technology Dispensing small and smallest quantities with volumetric precision and speed often presents major challenges for companies in the medical technology, automotive, electronics, biochemistry, and photonics industries. It is not uncommon for industrial manufacturing companies to integrate various dispensing systems from different suppliers into their lines in order to meet the chemical and … Read More

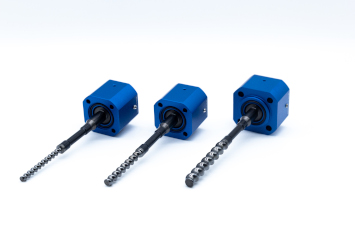

„Diamond Coated Rotor“ for preeflow

A new standard in the micro dispensing of highly abrasive Materials within the 1-component and 2-component range Precise, repeatable, and process-safe applications in the field of micro dispensing have always been the emphasis of the preeflow by ViscoTec brand. Thanks to the volumetric endless piston principle, almost all low to high viscosity materials can be processed. Solids-laden fluids, or filled … Read More

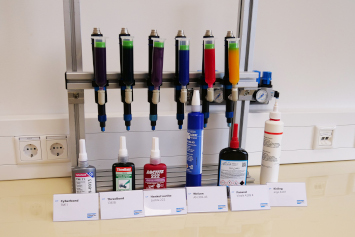

Dispensing anaerobic adhesives

Long-term tests with preeflow dispensers using one-component adhesives The word anaerobic means “without air” and therefore describes one of the two curing mechanisms in the handling of one-component adhesives: Air exclusion. Combined with the second mechanism, namely contact with metal ions, a rapid polymerization of the material is achieved. Due to their easy handling and fast curing, anaerobic adhesives enjoy … Read More

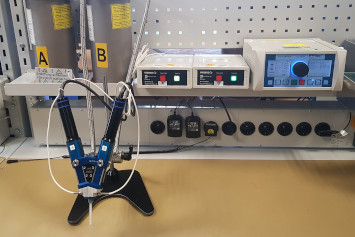

The very first eco-DUO450 has been in use for almost 10 years

A two-component dispenser shows its reliability in the dispensing of smallest quantities at SebaKMT In SebaKMT’s production facility in Baunach, an eco-DUO dispenser from the micro dispensing specialist’s preeflow line, has ensured proper dispensing from the get-go. The first eco-DUO450 two-component dispensers and was officially sold and delivered in 2011 with the serial number 0001. Precise dispensing of the high-performance … Read More

- Page 1 of 2

- 1

- 2