Covering the entire production process with one technology Dispensing small and smallest quantities with volumetric precision and speed often presents major challenges for companies in the medical technology, automotive, electronics, biochemistry, and photonics industries. It is not uncommon for industrial manufacturing companies to integrate various dispensing systems from different suppliers into their lines in order to meet the chemical and … Read More

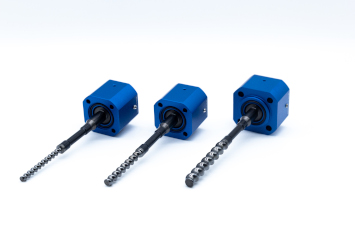

„Diamond Coated Rotor“ for preeflow

A new standard in the micro dispensing of highly abrasive Materials within the 1-component and 2-component range Precise, repeatable, and process-safe applications in the field of micro dispensing have always been the emphasis of the preeflow by ViscoTec brand. Thanks to the volumetric endless piston principle, almost all low to high viscosity materials can be processed. Solids-laden fluids, or filled … Read More

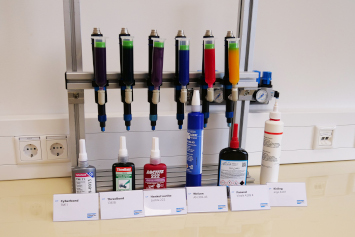

Dispensing anaerobic adhesives

Long-term tests with preeflow dispensers using one-component adhesives The word anaerobic means “without air” and therefore describes one of the two curing mechanisms in the handling of one-component adhesives: Air exclusion. Combined with the second mechanism, namely contact with metal ions, a rapid polymerization of the material is achieved. Due to their easy handling and fast curing, anaerobic adhesives enjoy … Read More

The very first eco-DUO450 has been in use for almost 10 years

A two-component dispenser shows its reliability in the dispensing of smallest quantities at SebaKMT In SebaKMT’s production facility in Baunach, an eco-DUO dispenser from the micro dispensing specialist’s preeflow line, has ensured proper dispensing from the get-go. The first eco-DUO450 two-component dispensers and was officially sold and delivered in 2011 with the serial number 0001. Precise dispensing of the high-performance … Read More

Stainless-Steel as an Alternative for preeflow Housing Components

New in the portfolio: Stainless steel kit for eco-PEN 300 to 450 Special requirements require special measures. To meet the requirements of customers and sales partners, preeflow has developed a stainless-steel kit for the eco-PEN dispensers 300, 330 and 450. These alternative housing components are now available and in stock. The stainless-steel kit is perfectly suited to convert a standard … Read More

Potting in Vacuum

Dispensing tests in the new laboratory of ViscoTec Asia Potting under vacuum is a frequently required application, especially due to increasingly small and complex products. In an application test in the new laboratories of ViscoTec Asia, the advantages of potting under vacuum are once again demonstrated. The video of the dispensing test is intended to support users and process managers … Read More

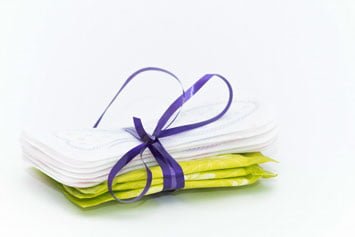

Fresh fragrance on feminine hygiene products

Smallest quantities sprayed continuously but flexibly A new project of ViscoTec Asia at the end of 2019 was the application of a fragrance on top of feminine hygiene products. Before implementation, dosing tests were carried out for the customer. A preeflow eco-SPRAY dispenser was employed for this. The aim of the tests was to check the dosing accuracy and repeatability … Read More

Microdispensing Technology from preeflow at Lopec in Munich

Brand of the dosing technology manufacturer ViscoTec as an exhibitor for the first time For the first time, preeflow is exhibiting at the Lopec in Munich. From 25th to 26th March, both 1- and 2-component microdispensing systems can be found in Hall B0 at Booth 120. The LOPEC (Large-area, Organic & Printed Electronics Convention) combines trade fair and congress for … Read More

Factors for Success in Dispensing 2-component Materials

preeflow eco-DUO dispensers have been committed to small quantity dispensing of fluids and pastes for the last 10 years In order to meet the requirements of the dispensing market, the first eco-DUO dispenser for the application of 2-component materials was developed in 2010. It was based on the preeflow eco-PEN dispensers. These dispensers ensured an automated dispensing, of precise and … Read More

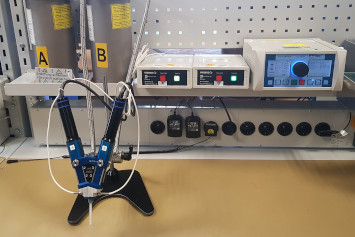

Dispensing in µl Range for Telecommunications Engineering

From manual application to a fully automatic production line In customer-specific dispensing tests in the preeflow technical center, the implementation of a fully automatic production of optical fibers, by using preeflow 2-component dispensers, was tested. More precisely, the tests focused on the bonding of optical fibers in a connector. The customer’s requirements were: A repeatable application of 5 µl of … Read More