Long-term tests with preeflow dispensers using one-component adhesives

The word anaerobic means “without air” and therefore describes one of the two curing mechanisms in the handling of one-component adhesives: Air exclusion. Combined with the second mechanism, namely contact with metal ions, a rapid polymerization of the material is achieved. Due to their easy handling and fast curing, anaerobic adhesives enjoy great popularity. The one-component, solvent-free adhesives are used in a wide variety of bonding applications. The main areas of application are, for example, screw locks, bonds with a sealing function in automotive applications, engine and transmission, and/or the connection of rotationally symmetrical parts.

In the past, the main advantage of anaerobic adhesives dispensing was also the main problem: the adhesive starts to react on contact with metallic components. Sometimes this reaction can be very quick. This is because in automated series production, the joined and bonded components should be processed as quickly as possible. This fast reaction is therefore desirable. However, in principle, each of the adhesives react differently.

preeflow dispensers by ViscoTec are ideal for the precise dispensing of anaerobic adhesives. This is because the use of suitable materials makes it possible to master the challenges of the application. In close internal cooperation with chemists from the ViscoTec Elastomer Department and through numerous long-term tests with anaerobically reactive adhesives, it has been possible to identify the materials that neither trigger a reaction in the adhesives, nor impair the performance of the preeflow dispensers. The preeflow eco-PEN dispenser housing, which comes into contact with the material is metal-free as a standard. The metallic parts of the rotor assembly which come into contact with the material, are treated in a simple process, and it is therefore ensured that curing cannot occur. Even extremely fast-reacting high-performance adhesives can remain in the dispenser for three days. The material does not react. Downtime over a weekend is no problem whatsoever. Even time-consuming and unpopular cleaning sessions on Friday afternoons are no longer required. The time saved by this, in addition to the avoided downtimes of the system due to unintentionally hardened material in the dispensing unit, bring a “return of investment” within a few weeks.

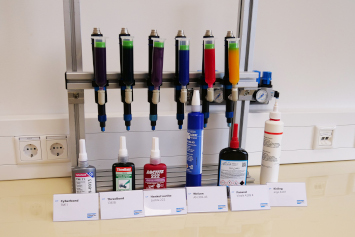

Test setup

Dispensing tests with the anaerobic adhesive

At the end of 2019, in order to further expand the experience in handling the anaerobic adhesives and to be able to advise customers even better in the future, the eco-PEN450 was subjected to long-term testing – in view of durability, resistance and behaviour in using the adhesives. A total of 14 different anaerobic adhesives from seven adhesive manufacturers were tested. The dispenser was operated in accordance with the instructions as described in the manual. After filling the dispenser with adhesive, approx. 3 ml (equivalent to the volume of the dispenser) were dispensed and the system was vented. The adhesive remained in the eco-PEN, without dispensing the material, for a period of up to 32 days in order to check the start-up behaviour with a torque measurement at the conclusion of the downtime. Even after 32(!) days standing time, a perfect dispensing result was achieved with most of the tested adhesives.

Result of the long-term tests

Overall, more than half of the adhesives showed no abnormalities whatsoever over the entire test period (icon “strong arm”, graphic below) and were able to remain in the eco-PEN for more than 32 days without dispensing. With three dispensers (Icon “X” after 32 days, graphic below) a cleaning step is recommended after the same number of days. For yet another three materials (icon “dispensing needle” after 1,2,8 days, diagram below) the effects of a slight polymerisation could be seen either on the dispensing needle or after a longer standstill period in the end piece of the dispenser. Here, adhesives that start to cure even under low light influence pose a great challenge to the dispensing system. The starting torque can be completely disregarded if the recommendations are followed, and did not show any increased values during the testing. In summary, if a carefully cleaned preeflow dispensing system is operated in accordance with instructions, there is nothing to prevent the use of anaerobic adhesives.

Downtime depending on viscosity

As usual, the preeflow products come out on top with the highest precision and repeatability in their dispensing results. Independent of viscosity fluctuations, clean, process-reliable dosing is achieved. In addition to anaerobic adhesives, a wide range of very complex fluids and pastes can be dispensed. From highly viscous materials such as epoxy resins or grease to low-viscosity fluxes. With over 30 years of experience, the preeflow team are on hand with advice and support for your dispensing projects.