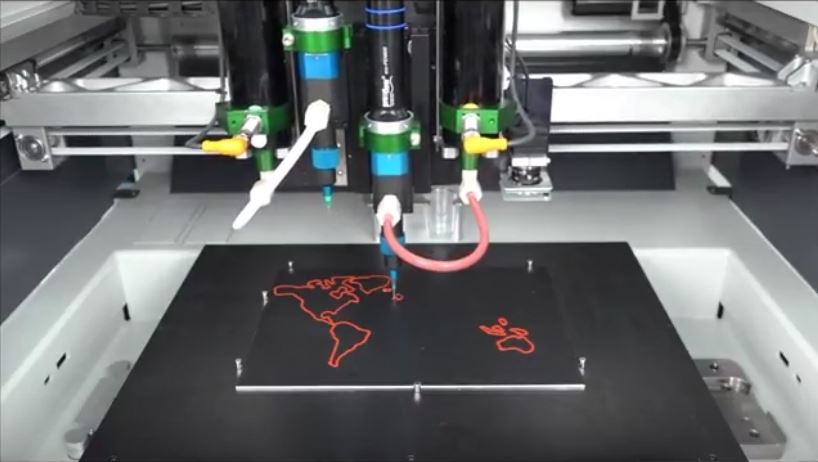

Fritsch dispensing machine with integrated preeflow dispensers

The fully automated dispensing system, dispenseALL420 from Fritsch GmbH in Kastl / Utzenhofen, is a flexible system for the dosing of a variety of different materials. With the integrated preeflow eco-PEN600 dispensers from ViscoTec, a high-precision, clean dosing solution is achieved. Materials such as pastes, adhesives, silicones, greases, varnishes or similar fluids are applied with repeatability and absolute precision – either as a bead or as a dot application.

The system can be used for prototypes, for serial production, for special applications or to extend an existing production line. The dosing tasks are as individual as the media used. The dispenseALL420 provides a universal base on which to perform various tasks optimally.

Andreas Hiller, Sales / Application at Fritsch GmbH has agreed to answer a few questions about the development and implementation of the project:

preeflow: How did using preeflow dispensers come about? How were you made aware of the products?

Andreas Hiller: Fritsch received a request from a customer to fill a circuit carrier with silicone. To carry out this task, a dispenser should be implemented to meet these high customer requirements. Since Fritsch has many years of experience in the field of dosing, the preeflow system was already known to the company. From previous projects, we know that the preeflow eco-PEN meets the requirements more than enough.

preeflow: What special requirements do the dispensers need to fulfil in order to be used in your units?

Andreas Hiller: Particularly important for us and our customers are high repeatability, precise processing of various material, user-friendly handling and short set-up times. These properties characterize the preeflow dispensers.

preeflow: Which advantages does the preeflow dispenser from ViscoTec have over other manufacturers? And therefore, what impresses you about the technology?

Andreas Hiller: The preeflow eco-PEN enables a constant volume dosing of a wide range of material. In doing so, influences, such as the ambient temperature are compensated for. This is the basis for a reproducible result.

More than 10,000 dispensers of the preeflow brand have already been successfully implemented worldwide. Also in this application, the endless piston principle has again been proven. The shear-sensitive technology, based on the progressive cavity pump, is impressive in a micro-dosing system, with its high-precision and clean dosing results.

About Fritsch GmbH: High-performance SMD machines are of the utmost importance in order to be able to produce reliably working components and assemblies. The company Fritsch, which has existed for nearly 40 years, successfully stands for comprehensive and flexible solutions in the field of SMT technology – from a stencil printer – to SMD automatic pick & place machines, as well as SMD dispensing machines.

Video to the application example:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.