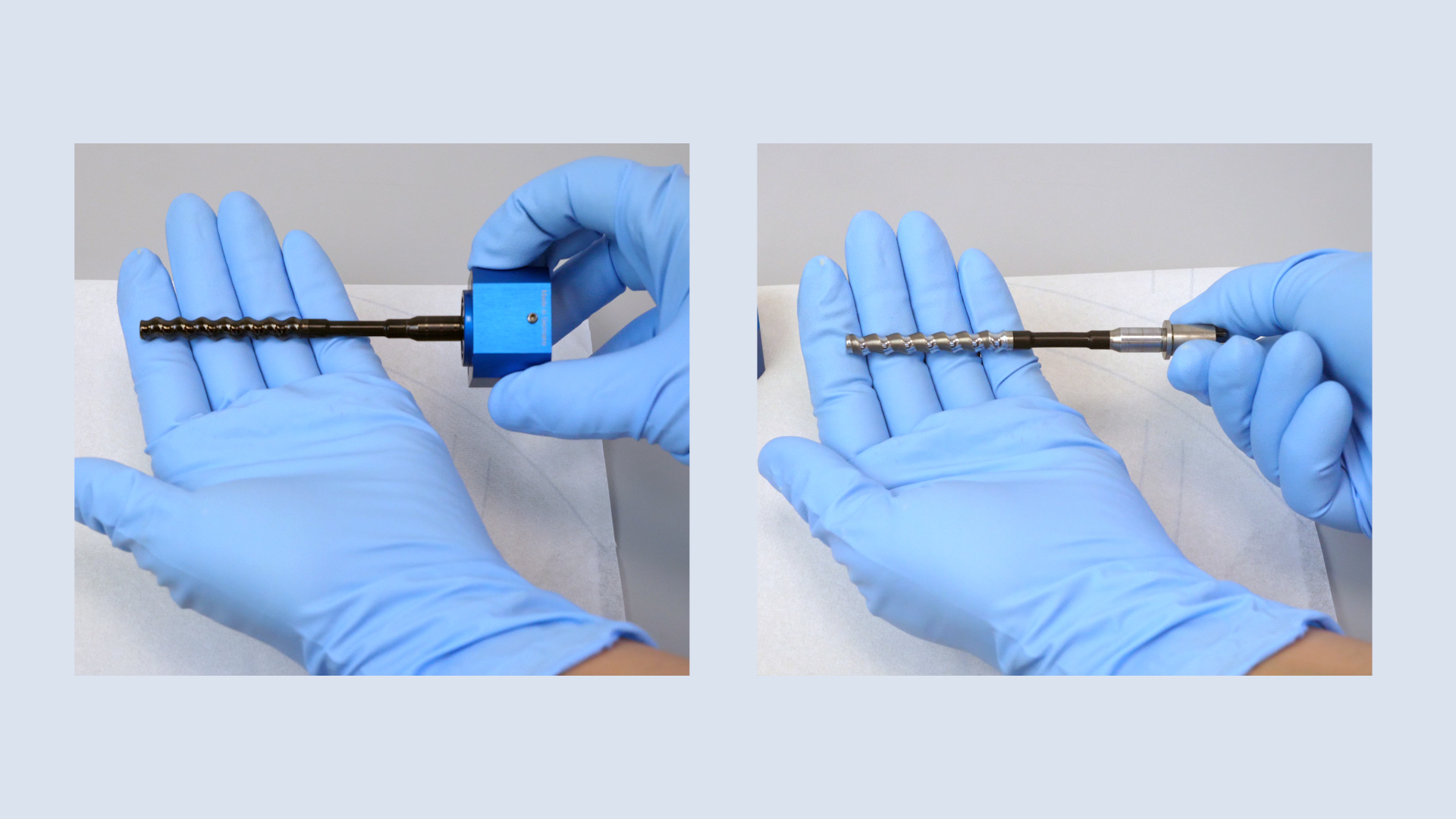

eco-PENs that are already in operation can be upgraded in a very short time, thanks to the spare parts kits.

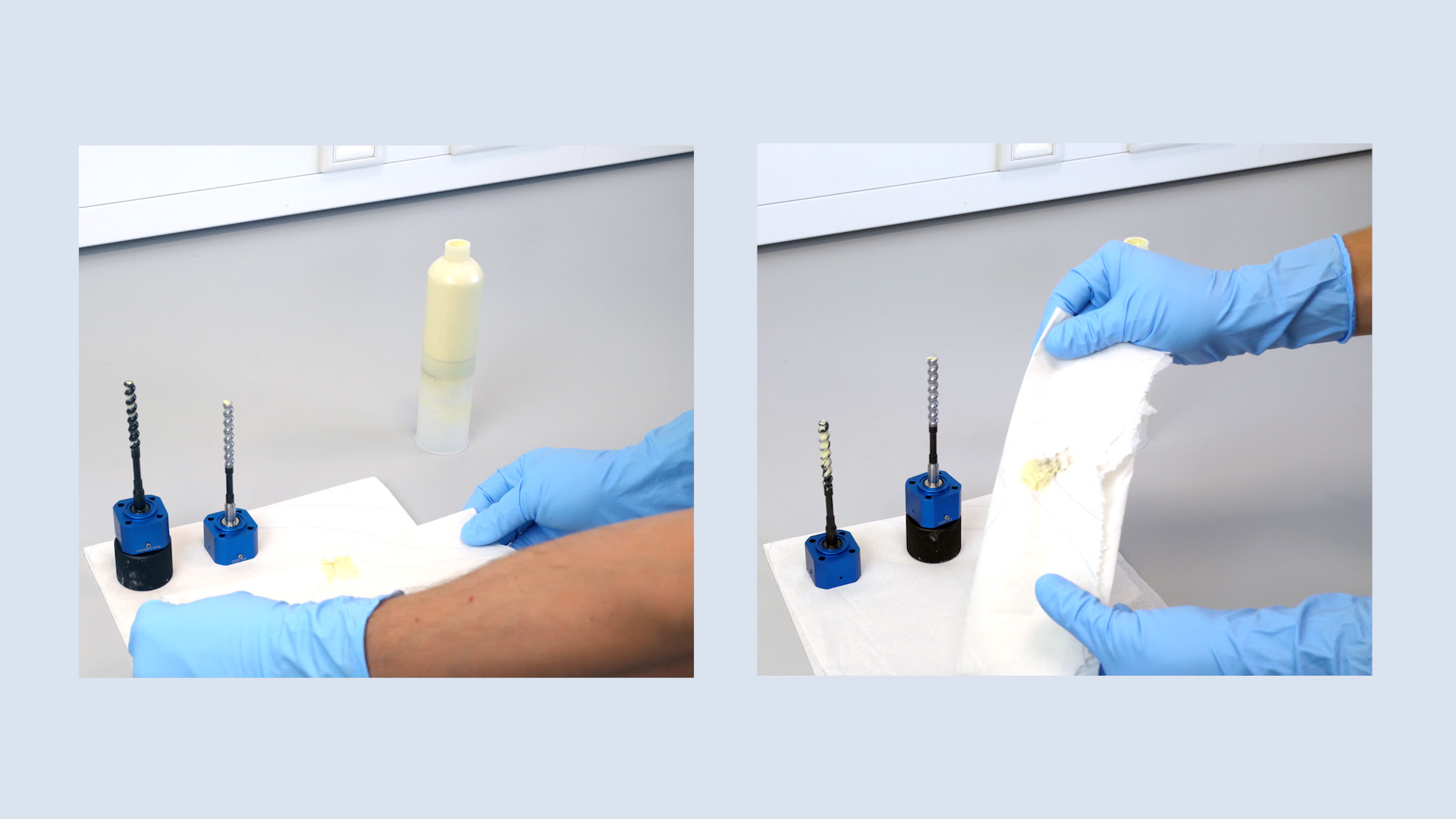

Test result after 120 hours dispensing: The standard rotor on the right, with a hard chrome layer, shows signs of wear over time when used with highly abrasive materials, depending on the process.

Detail view rotor wear: Standard rotor left with hard chrome coating

Test result: With some materials discoloration occurs when the standard hard chrome equipment is used.

300 % longer service life and no material discoloration thanks to preeflow® DC rotors

preeflow introduced the Diamond Coated Rotors (DC rotors for short) just a few months ago and the demand is already exceeding the expectations of the microdispensing technology specialist. The results achieved at laboratory level and during field tests, with regard to improving the service life when processing highly abrasive materials, have been confirmed and even exceeded in specific applications.

The coated rotors are not only impressive in terms of service life optimization: Some materials tend to discolor if they are applied with the standard hard chrome-plated rotors. This undesirable phenomenon no longer occurs when using DC rotors. preeflow customers worldwide are enthusiastic about this technically innovative solution for dispensing challenging and especially highly abrasive material. Process reliability and service life are consistently impressive.

DC rotors are a combination of different coatings and finishing processes specially developed for this purpose. This unique multilayer principle enables a previously unattainable surface hardness for rotors made of metal. This considerably exceeds the surface hardness of the standard hard chrome-plated rotors and also offers advantages in terms of friction between the rotor and stator. In addition, some chemical reactions that occur when a hard chrome layer comes into contact with some dispensing materials are prevented. Complimentary to the DC rotor is the already established VisLas stator, which is particularly suitable for abrasive materials.

Tests with challenging materials confirm the possibilities for optimization

In order to enable preeflow dealers, ViscoTec branches and users to make even better claims regarding the service life and performance of the DC rotors, basic tests on the service life of the system and material discoloration were supplemented by tests with extremely challenging materials.

Service life of the preeflow dispenser when applying highly abrasive gap fillers

With a preeflow eco-PEN600 approx. 1.3 million dispensing shots could be made without the dispensing result changing significantly during this period. Over 100 kg of material was processed. It is known from comparable tests that the standard rotor with a hard chrome layer shows signs of wear after around 10 % of these dispensing shots with similar, highly abrasive gap fillers.

Solving the problem with discolored material

With some materials, discoloration occurred in the first few dispensing applications when the standardized hard chrome equipment was used. In such cases, this is not due to abrasion, but to a reaction of some of the ingredients with the hard chrome layer of the rotor. With the use of a DC rotor with its special multilayer coating, this phenomenon can be eliminated - permanently.

The DC rotors are the right product at the right time in view of ever-smaller electronic components with their increasing demands regarding temperature management. For successful implementation, it is necessary to apply partly highly abrasive gap fillers in the smallest quantities precisely, with repeatability and process reliability. Rotors with DC coating are perfect for applications in the microliter and milliliter range. They combine numerous advantages in one product:

- Stable dispensing process even with chemically reactive materials

- Optimized service life, longer maintenance intervals for increased productivity

- Cost reduction through lower spare parts requirement

- Short changeover times, upgrade of already in operation eco-PENs possible