Precise adhesive dispensing to components

Thanks to its experience and reliability preeflow is the perfect partner in numerous dispensing applications – also when it comes to bonding loudspeaker components. In the loudspeaker bonding a great value on exact processing is placed to achieve an outstanding sound experience and create long-lasting products.

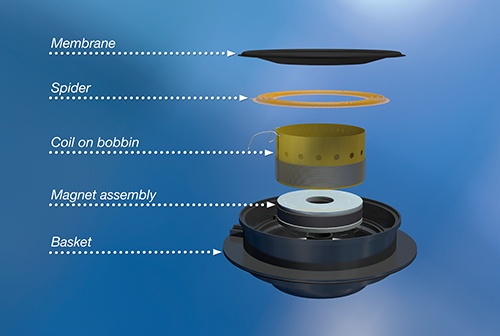

The loudspeaker manufacturer’s latest technical innovations place high demands on every single component. That´s why top quality and reliability are required from for example pot, membrane and cover. Ensuring the quality of the complete finished product starts at the beginning of the process chain. Bonding respectively adhesive application is one important point here.

The loudspeaker manufacturer’s latest technical innovations place high demands on the single component parts. Source: DELO Industrie Klebstoffe

High requirements to the dispensing technology

On one hand the bonding has to resist external environmental influences like high temperature variations, vibration or moisture. On the other hand adhesive residues on the edges or overflowing adhesives between two assembled parts are a real no-go. The dispensing task depends on a defined form of the loudspeaker. Specific contours have to be respected and speed has to be varied. Curves in the dosing bead are critical areas: They are performed at smaller speed to avoid material accumulation or overlapping of the two bead endings. Also fluid dripping or stringing at the end of each single dispensing task has to be prevented. Total uniform application is essential.

Requirements in a dispensing system for this branch are primarily: A most precise bead dispensing and an absolute repeatability in fast processes! That´s why loudspeaker manufacturers depend on competent partners with whom they can ensure the unique quality of their products at every stage. Only proper bonding provides perfect hearing and permanent audio enjoyment. preeflow products are integrated in dosing applications like this worldwide. The unique quality – Made in Germany – turns them to indispensable components in these related challenging areas.

Precision volume dosing instruments such as eco-PEN and eco-DUO offer stable dosing in the loudspeaker bonding sector.

High-precision bonding of loudspeaker components

Precision volume dosing instruments such as eco-PEN and eco-DUO offer stable dispensing results. There are various areas in a loudspeaker to be glued and preeflow devices can perform them all perfectly: Bonding of coils, magnet system, membrane damper adhesives, wire fixation and contact protection. The preeflow series replaces products of other manufacturers in a lot of applications because they were not able to withstand the high demands of the market. Next to UV-curing adhesives also two-component adhesives and every other kind of adhesives that shows a viscosity from watery to pasty are processed. Smallest adhesive quantities starting from 0.001 ml can be achieved and this with a repeatability higher than 99 %.

The complete preeflow portfolio uses the established ViscoTec endless-piston-principle which makes it possible to achieve a purely volumetric, pulsation-free dispensing process. The dosing behavior can be proportionally driven straightaway and therefore it is very easy and fast to apply exactly and reliably one- or two-component adhesives. The performance characteristics remain the same whilst processing at the same time fluids with different viscosities for application with a big difference in the mixing ratio when handling two-component materials.

A stable dispensing is ensured thanks to the precision volume dosing equipment such as the eco-PEN and the eco-DUO or the eco-SPRAY. preeflow products present ideal properties to match industry requirements and to even exceed them. From small smartphone loudspeakers to huge high-end boxes the dispensers have already enforced themselves in various loudspeaker applications – also in comparison with the competition. Please convince yourself!

You can see the precise application in the preeflow video, the How To Machines video shows the speaker manufacturing process:

|

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers. |

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers. |

|---|