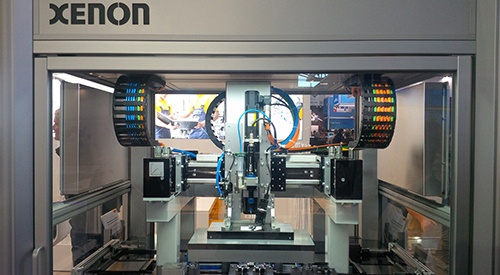

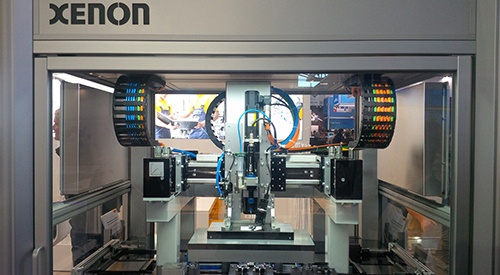

The eco-PEN 450 from preeflow, by ViscoTec, convinces as a part of the precision dosing system with vacuum option from XENON. Thanks to the reliable dispenser of the medium-sized dosing specialist from Töging customers receive a fully automated dosing system. This stands for absolute precision and repeatability: The system and the included components as well as the dosing process itself. Both, XENON and ViscoTec benefited from decades of experience and know-how when it came to developing and the implementation of the project.

XENON Automatisierungstechnik GmbH projects, develops and builds up machines and systems for the automation of production processes. As a leading provider of complex and turn-key installations the company opens up the possibility of applying on diverse components and even under vacuum. But it is the combination with an eco-PEN from preeflow that allows a consistently high quality dosing and absolute accuracy.

On the basis of the accumulated experiences of XENON with eco-PENs and the adequate, desired dosing volume range of the dispenser, the decision was made for preeflow. Implementing the components is uncomplicated: “The progressive cavity pump is controlled directly by the plug`n`dose box and the SPS. Due to this the volume rate can be brought to the travelling path without complications.” says XENON. While other dosing pumps have difficulties with the applied vacuum, the dosing process can be fully controlled with the eco-PEN. It turns out to be the best volumetric dosing solution for this application. Additional advantages like easy integration to automated systems and simple implementation convince in the application.

On the basis of the accumulated experiences of XENON with eco-PENs and the adequate, desired dosing volume range of the dispenser, the decision was made for preeflow. Implementing the components is uncomplicated: “The progressive cavity pump is controlled directly by the plug`n`dose box and the SPS. Due to this the volume rate can be brought to the travelling path without complications.” says XENON. While other dosing pumps have difficulties with the applied vacuum, the dosing process can be fully controlled with the eco-PEN. It turns out to be the best volumetric dosing solution for this application. Additional advantages like easy integration to automated systems and simple implementation convince in the application.

The main goal was high repeatability during the whole dosing process. With the directly driven axes used one single axis reaches +/- 10 µm. The z-axis is performed as a spindle. The composition is chosen as gantry. The transverse axis can be realized in 2 different installation sizes. A strengthened axis is installed in the finished machine, which can move masses up to 20 kg. A necessity when it comes to dosing in vacuum and with this appropriate components have to be moved (air bearing incl. excavation unit). Heavy multi-component dosing valves can be used, too. For dosing tasks with lighter dosing units (like for example the eco-PEN) without vacuum option an axis with lower load also can be chosen. A typical weight for such dosing compositions is 5 kg. It is possible to respond to special customer requests with this modular system without the need of deviating from standardized solutions.

Incidental dripping and the necessity of a great needle length are potential difficulties in dosing processes under vacuum. Those were also special challenges for the preeflow products. Therefore dosing valves working on time pressure principle are not appropriate for XENON’s process reliable and precise dosing processes. This is the reason why a preeflow volume dosage system had to be used: The volume rate respectively the output has to be adjustable for the required flexibility. Additionally the price-performance ratio was convincing. However the most important for XENON was the compact design, the flexibility concerning maximal dosing volume and the controllable volume rate. Once again preeflow could prove microdispensing in perfection.