eco-CONTROL EC200 2.0 combines the benefits of a 1-component control unit with state-of-the-art features for 2-component dosing

It has been one year since the eco-CONTROL EC200 2.0 hit the market. ViscoTec, headquartered in Töging, Germany, is proud to announce the control unit now has the ability to handle 2-component dispensing. The main goal of this product development was to provide customers with an all in one unit that offers highest flexibility of operation and control.

2-component dosing control with eco-CONTROL EC200 2.0

Hardware and software management is the basis of this new control unit. Customers are now able to adapt their control unit for new/changing dosing requirements/production parameters long term by purchasing the relevant licence.

The eco-DUO dosing system control permits precise dispensing of two-component substances in the desired mixing ratio and with repeat accuracy. Users have the choice between gravimetric or volumetric mixing.

The control unit offers dosing pressure monitoring as well as temperature monitoring. Customers that use the 2-component dispenser with the flowplus-SPT M6 can connect it directly to eco-CONTROL EC200 2.0 and start dosing as a closed loop system immediately. It is also important to note that the new control unit supports manual rinsing of 2 components – flowrate and quantity can be set manually.

The dosing pressure is displayed as a bar graph and the pressure trend is displayed in a diagram. After an upgrade is carried out, customers with a 1-component control unit will also be able to work with a dosing monitor in the future. Pot life monitoring now has a blank shot function and enables any flowrates and quantities.

If you want to monitor the application and the metering pressure curves of beads, you can do this with the aid of the envelope curve, among other things. Active and passive edges can be displayed in the control box mode. If the user is focussed on dot-dosing, the display is integral. Rising/falling edges of the dosing pressure can be illustrated by selecting/de-selecting a checkbox, which ensures precise monitoring.

The eco-CONTROL EC200 2.0 also offers the option of counting doses with the relevant status – o.k. and not o.k. In total, users can select up to five options for dosing pressure monitoring. All of this was possible due to the feedback and support from ViscoTec's customers, as well as ViscoTec's sales department maintaining close contact with the engineering and design team during technical development. The results of the field research were directly incorporated into development. The eco-CONTROL EC200 2.0 now makes things easy for users in that it independently adapts the limits of the respective setting - such as the envelope curve - to the dosing. However, manual modifications can also be made here. RS232 makes logging even large amounts of data simple, which means new Industry 4.0 technologies can be used. Through activation of the digital input signal, the newly launched 2-component control unit enables multiple start/stop doses to be saved in a measurement and direct pressure monitoring for an entire component, in addition to the features familiar from the 1-component control unit (IO test, NPN/PNP switching, etc.).

Inlet pressure monitoring by preeflow

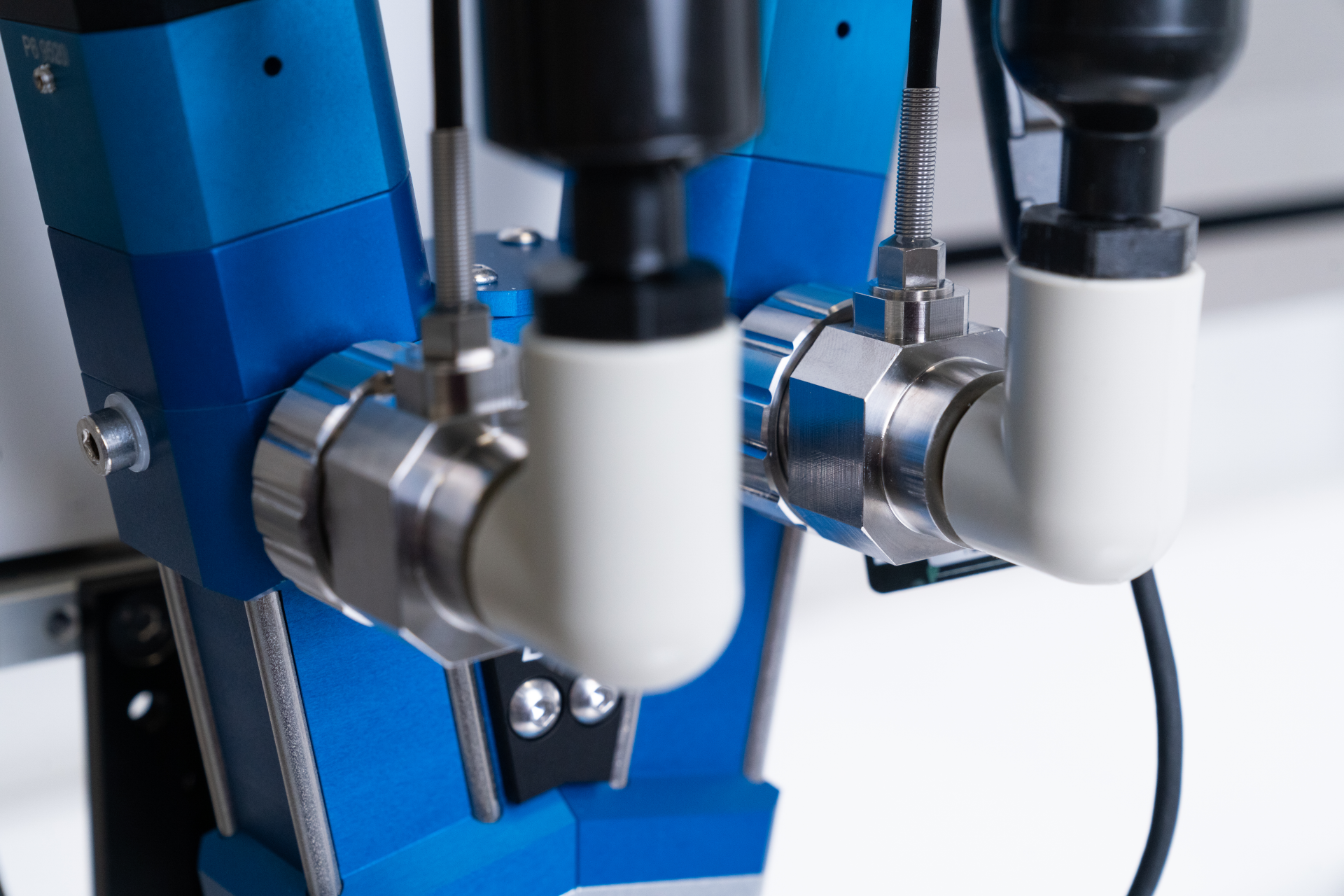

Inlet pressure adapter set for the eco-PEN and eco-DUO series

Preeflow offers an additional process monitoring option with the inlet pressure adapter set for the eco-PEN and eco-DUO series.

All Systems with an eco-CONTROL EC200 2.0 can be extended with the inlet pressure unit for a full process monitoring of the dosing process.

This enables better process control and thus increased process reliability and product quality for your production.