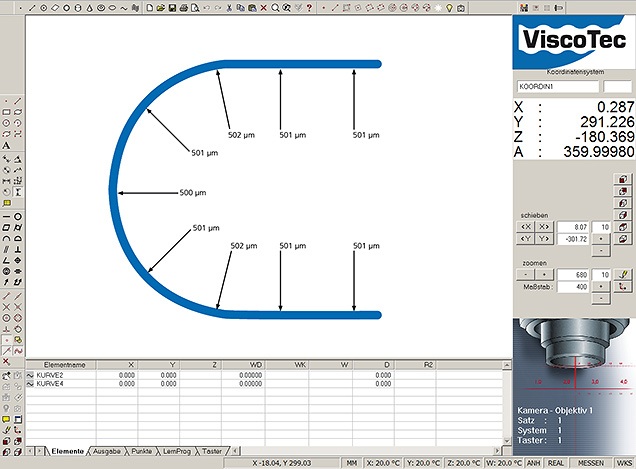

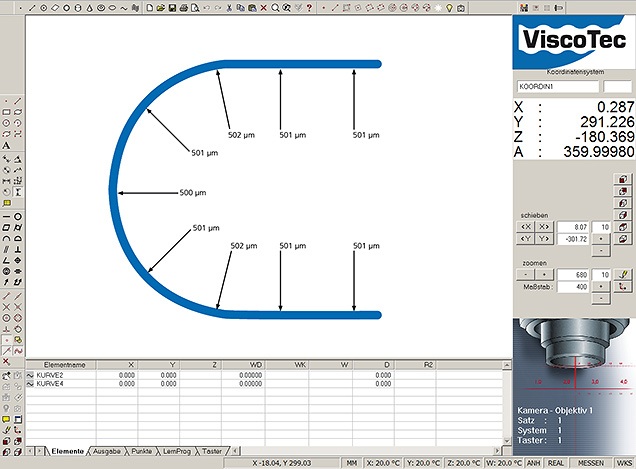

preeflow® dosing systems are among the world smallest progressive cavity pumps on the market. The unique endless-piston principle is the basis for the linear regulation of the volumetric dosing through the rotation of the rotor. The precision of the exclusively in Germany manufactured volumetric dispensing pumps is responsible for the high precise dynamix-factor of less than 1.5 %. The so-called dynamix-factor ensures that dosed beads with radiuses or curve geometries are continuously controllable and proportional to the dosing speed. Changes or adjustments of the traverse speed for robot or benchtop axis systems is not necessary any more. A gentle traverse speed and thus constant G-forces improves the precision of the dosing results. This major advantage for fully automated application processes is a standard feature for all preeflow 1-K and 2-K products.

Optimum dynamix-factor provides a constant traverse speed with robot or benchtop axis systems