Dispensing tests in the new laboratory of ViscoTec Asia

Potting under vacuum is a frequently required application, especially due to increasingly small and complex products. In an application test in the new laboratories of ViscoTec Asia, the advantages of potting under vacuum are once again demonstrated. The video of the dispensing test is intended to support users and process managers in finding solutions.

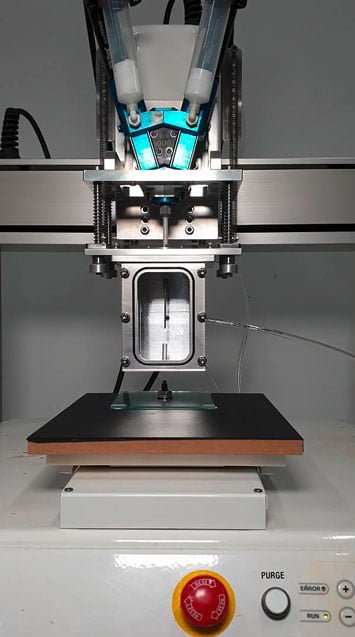

Video Screenshot

Initially, a customer of ViscoTec Asia approached the dispensing specialists with a request for a solution. In his application, a hole with a diameter of 2.8 mm had to be potted. The primary goal is to achieve a potting time of less than 10 seconds – completely without entrapped air. This is made more difficult by the fact that the casting area below the hole consists of metal coils which are prone to trapping air bubbles.

Initial dosing tests without vacuum showed that the potting can only be completed in 24 to 32 seconds and at a lower flow rate. Additionally, cavities were found in the cured material. After implementation of the vacuum chamber, the process could be completed in under 10 seconds. And above all: Without cavities in the cast material. For higher productivity and better quality.

The tests could be carried out with the standard equipment in the new test laboratories. This includes: A preeflow eco-DUO 2-component dispenser, a tabletop robot, a vacuum pump and the vacuum chamber. Melvyn Teo, Managing Director of ViscoTec Asia about the tests: “We know that simplicity is always preferred, so vacuum potting is only recommended when necessary. The solution depends on the customer’s expectations, the application and the product design. It is important that we clarify the details in close cooperation with our customers before deciding what is best suited”.

ViscoTec Asia has already carried out several dosing tests with the vacuum chamber. In most cases these were tests for the encapsulation of sensors. The sensors are getting smaller and smaller and encapsulation is required to keep the internal elements in position to make them robust and durable. Vacuum potting is mainly aimed at components with small openings and complex internal structures.

“We are always glad to work with our customers and find solutions together. As a supplier of reliable dispensing solutions, we have experience in a wide range of industries and applications. We are happy to share this experience to help our customers find solutions for their specific applications,” Melvyn Teo continues.

The results of the dosing tests of casting under vacuum can be seen in the video:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Further information on the wide range of applications for the preeflow dispensers can be found here: https://www.preeflow.com/en/products/