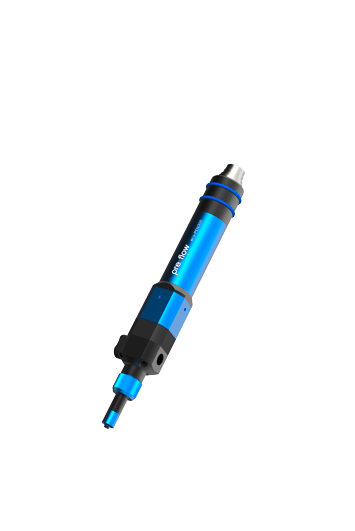

Your Dispensing Device for Single-Component Fluids

preeflow® eco-PEN

preeflow® positive displacement pumps stand for high-quality products, from control units to industrial dispensers. Always following our philosophy: “smaller, more precise, economical”. They are suitable for manual workstations as desktop devices or for automated operation. But also, as a built-in device in control cabinets or as front panel modules.

1-component dispenser: The preeflow® eco-PEN is impressive

Valveless sealed technology without dripping

Dosing pressures of 16 to 20 bar are possible

Smaller needle and nozzle cross-sections

Pressure tank maybe dropped, depending on material

Smallest dispensing quantity: 0.25 µl

Dosing accuracy ± 1 %

Repeat accuracy > 99 %

Products in detail

It must be good if it’s being copied! Fortunately, our products are so successful that there are always companies who want to sell them – even without our permission. That’s why they try to copy our products and partly even sell them under our name. When dealing with counterfeit products there can be big differences in quality. preeflow is not liable for copied products. We will be happy to tell you where you can obtain original products and accessories, for which we promise 100 % quality and reliability!

Smallest dispensing quantity: 0,25 µl

Adjustable dispensing flow: 0,0044 – 0,35 ml/min

Weight: 175 g (without cartridge and holder)

Description

The eco-PEN XS 180 dosing pump from preeflow enables high-precision dosing of a wide variety of materials with different viscosities in the nano and microliter range.

Theory of function

The preeflow eco-PEN XS 180 is a rotating and perfectly pressure-tight displacement system. The dispenser comprises of a self-sealing rotor and stator. Conveyance action by material displacement in the stator through controlled rotor rotation. Safe conveyance without any modification of the dosing material. With its suck back option, preeflow ensures clean and controlled material or medium cut-off while preventing post-dripping effects.

Datenblatt eco-PEN XSControl units

Description

The eco-CONTROL EC200 2.0 control unit from preeflow simplifies the dispensing process. It is perfectly suitable for our eco-PEN series.

Theory of function

The control unit is primarily used to control and parameterize the preeflow dispensers. Pressure monitoring is also possible. For a process-reliable process with precise dispensing results. The control unit can be easily integrated into fully automatic systems and meets all requirements of modern dispensing processes. With an integrated power supply unit the eco-CONTROL EC200 2.0 offers a compact solution.

The control unit also offers possibilities for pressure and temperature monitoring, 100 program memory locations and enables fast, clear storage of programs. Integration in large systems with PLC is possible.

The dispensing control unit is available as a desktop version, monitor version or a built-in version.

Data sheet eco-CONTROL EC200 2.0preeflow® – automated dispensing systems

More than 25 years of experience in fluid dispensing. ViscoTec distinguishes itself with its comprehensive know-how in dispensing technology. In 2008, this wealth of experience was expanded with the introduction of the preeflow brand. With success: For more than 15 years, preeflow has stood for precise and purely volumetric dispensing of fluids in small and very small quantities. All over the world, a wide variety of industries rely on preeflow dispensing products. Always following our philosophy: Smaller, more precise, economical.