The preeflow eco-SPRAY enables volumetric dispensing of low to high viscosity media based on the endless piston principle. A defined quantity of material is fed into the special low-flow spray chamber under processor control. The eco-SPRAY atomizes or sprays the material continuously or selectively with high edge definition and minimal overspray − for optimum spraying results.

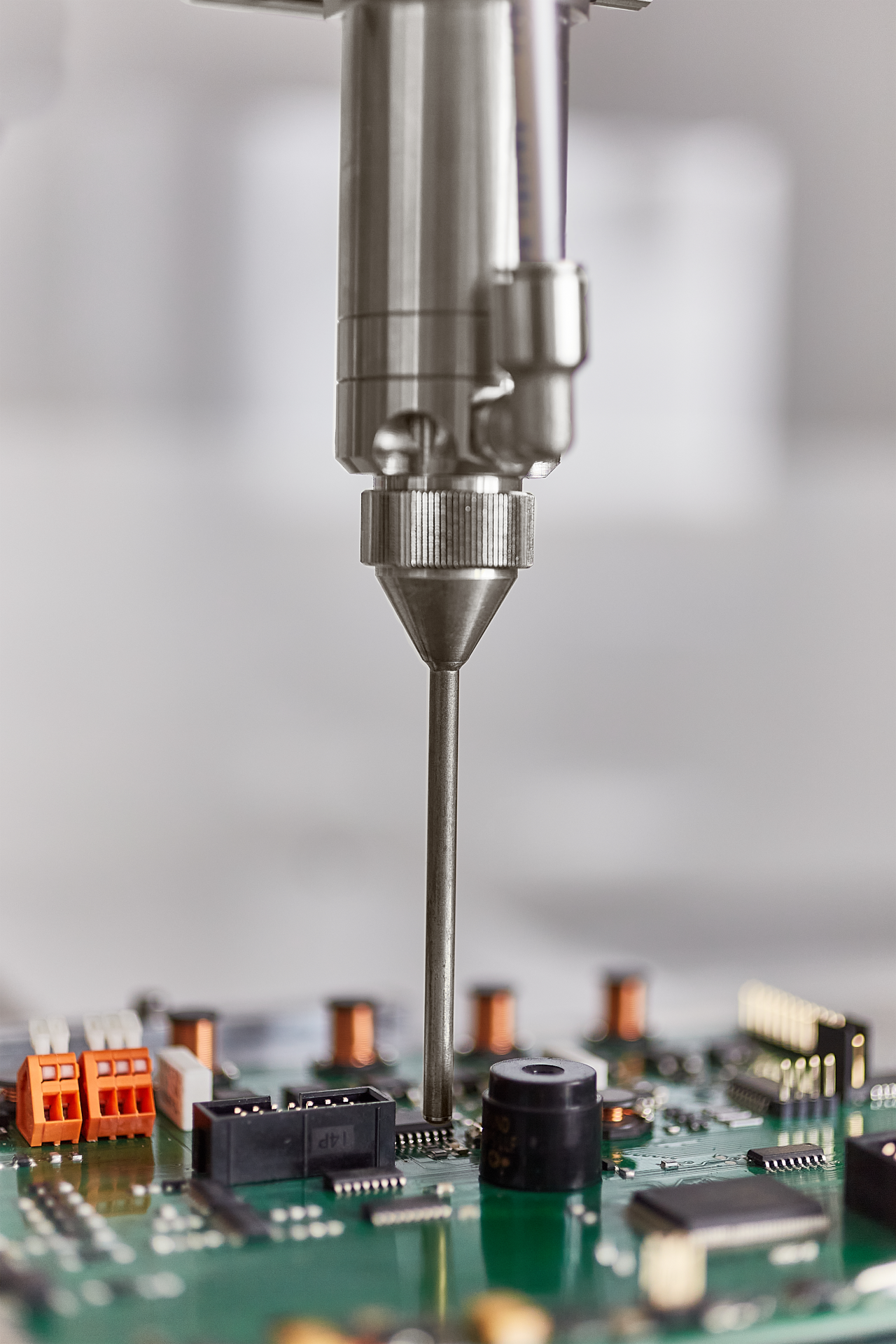

New spray needle extension for the eco-SPRAY

The eco-SPRAY is mainly used in automated spraying applications such as the production of circuit boards. Here it is particularly challenging to prevent component collision on the circuit boards - not an unknown problem in electronics production. This is because electrical components and the applicator also get in each other's way when assembling PCBs or applying protective lacquers in conformal coating applications. preeflow now has a proverbially slim solution: the spray needle extension with a standard length of 61.5 mm is available as an option for the eco-SPRAY. Other variants can be requested and tested at any time.

Particularly when processing highly viscous materials, the eco-SPRAY with the optional spray needle extension can apply and precisely define exact quantities regardless of viscosity and pre-pressure. Depending on the desired layer thickness, the dosage can be adjusted by simply changing the air pressure, adhesive volume, distance to the substrate or the speed of the application. The sophisticated technology of preeflow and its extensions help to increase efficiency and quality in electronics production worldwide.