A two-component dispenser shows its reliability in the dispensing of smallest quantities at SebaKMT

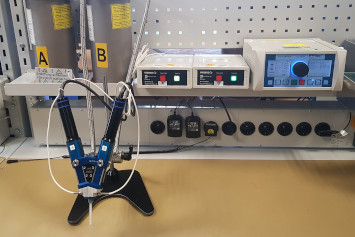

Semi-automatic dispensing workstation

In SebaKMT’s production facility in Baunach, an eco-DUO dispenser from the micro dispensing specialist’s preeflow line, has ensured proper dispensing from the get-go. The first eco-DUO450 two-component dispensers and was officially sold and delivered in 2011 with the serial number 0001. Precise dispensing of the high-performance silicone Wacker SilGel 612, protects components from corrosion: the Baunach plant manufactures, for example, noise loggers for acoustic zone monitoring of drinking water supplies and ground microphones for cable fault location in the medium-voltage network. SebaKMT is a member of the British Megger Group, a leading global supplier of measuring and testing equipment for the energy industry.

Sebalog N-3: Network-compatible noise logger for acoustic zone monitoring

The noise logger from SebaKMT is a device for the acoustic monitoring of pipeline systems and is, for example, capable of transmitting measurement data via GSM directly to the control centre using a network mode. This enables a targeted search for leaks at those locations where there the highest probability of leakage exists. This effective pre-location method saves the drinking water supplier time and money.

digiPHONE+ NT Set: all-round tracking receiver

The ground microphone is part of the digiPHONE+ NT set; an all-round tracking receiver. SebaKMT has combined two systems in one device: firstly, a ground microphone for locating flashover faults in underground cables and secondly, an earth fault locator for locating sheath faults in plastic-insulated PE and XLPE medium-voltage cables.

Both processes are implemented in a semi-automatic dispensing application. The following challenges are placed on the dispensing equipment: in order to achieve the required mixing ratios of the two casting components and repeatable results, dispensing must be carried out with high accuracy. In spite of frequent and longer production-related downtimes, the previously defined quantities must be applied repeatedly and accurately. The eco-DUO450 was impressive with its strong performance right from the start.

In all these years, it has only once been sent to the preeflow Service Center for a prophylactic check. There, during a longer downtime in SebaKMT production, it was cleaned and maintained, and the seals were replaced. After the two-component dispenser was returned, operations could continue as planned.

Petra Hofmann, Quality Officer at Seba Dynatronic Mess- und Ortungstechnik GmbH in Baunach, says of the two-component dispenser and the cooperation with preeflow: “We are very satisfied with the performance of the eco-DUO450. The system has been reliably meeting our requirements for many years with minimum maintenance”.